TRAP TECHNOLOGY CLIENT FACTORY TOUR

Goodnature Discover Hidden Opportunities With

Linkeight’s Guided Factory Tour

Navigating global manufacturing is tough - especially for Kiwi businesses seeking reliable long-term partners.

At Linkeight, we’ve seen first-hand how our guided factory tours have helped businesses avoid costly missteps and achieve manufacturing success.

Robbie van Dam, Co-founder and Director of Goodnature, joined us for a factory tour through China late last year, and his experience sheds light on the value of these tours for Kiwi businesses.

Direct Communication Bridges Critical Gaps

When it comes to overseas manufacturing, nothing beats face-to-face communication. Robbie shared how this direct interaction made all the difference in aligning with factory owners: “We had the opportunity to engage directly with the factory owners to really align with what’s important for our product programme. We could communicate, with the help of Susan in particular, what was critical and what’s a nice-to-have.”

This level of communication allowed them to convey details and nuances that might have been lost in emails or video calls. Having the chance to demonstrate functionality and observe body language during discussions is something that’s simply impossible to replicate remotely.

Navigating China’s Manufacturing Landscape with Confidence

China’s manufacturing landscape is vast, and even experienced business travellers can feel overwhelmed by the sheer scale and variety of options available. Robbie reflected on how challenging it could have been to navigate without Linkeight’s support: “It’s a big country to navigate and really would have been impossible to do so quickly without the Linkeight team.” Trying to make the right decisions on manufacturing partners in a market of that size could be daunting, especially for a smaller business. He also emphasized the advantages of Linkeight’s established presence: “It would have been nearly impossible to do this as a small company. We are now effectively a design team with access to many ways of manufacturing.”

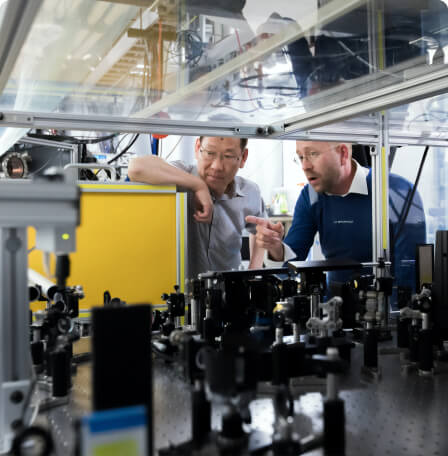

Discovering Hidden Manufacturing Opportunities

One of the most valuable benefits of a factory tour is the unexpected discoveries that come from being present in the factory environment. Robbie noted that standing on the factory floor opened his eyes to possibilities he hadn’t considered from New Zealand: “Finding hidden gems that can make other cool parts or things,” something he explained could only happen when you’re physically there to observe machinery, processes, and finished products first-hand.

Leveraging Linkeight's Established Network

Linkeight’s extensive network across China’s manufacturing hubs is another critical advantage. Robbie was quick to point out the strength of these relationships: “They have a big network that’s pretty hard to match!” This network provides Linkeight clients with more than just access to factories – it opens doors more easily, builds trust at the outset of negotiations, and establishes a foundation of mutual respect that simply isn’t possible when starting from scratch.

Focus on Your Product, Not the Logistics

Coordinating multiple factory visits across various manufacturing centres can be a logistical nightmare. Robbie was relieved that Linkeight handled all the details, which allowed him to focus solely on his product decisions: “To be honest, I didn’t have to think about where we were… Susan had a very clear itinerary.” With the Linkeight team managing all the complex logistics, clients like Robbie can dedicate their energy and attention to product development instead of navigating the logistical challenges.

Expanding Manufacturing Horizons

Factory tours also offer networking opportunities that extend beyond immediate manufacturing needs. For Robbie, it was clear that the possibilities were endless once he realized how many manufacturing options were available: “We met some potential other manufacturers but mostly, we’re open to being able to make anything we can think of because we know we can find a manufacturer with Linkeight.” This expanded perspective often leads to product innovations and business opportunities that were previously off the radar.

The Bottom Line: Seeing Is Understanding

When asked if he would recommend factory tours with Linkeight to other Kiwi businesses, Robbie’s answer was simple and direct: “Do it! You can’t possibly understand why things are made there without a visit!” His words capture the essence of why our factory tour service is so valuable — some aspects of manufacturing can only be truly understood by experiencing them first-hand.

Linkeight helps Kiwi businesses - both large and small - navigate the complexities of overseas manufacturing.

We offer guided factory tours for our existing clients, as we’ve seen the benefits to help their businesses open doors to new opportunities and ensure they’re making the best, most informed decisions about their manufacturing needs.

Ready to take the next step? Let’s start your Linkeight journey – get in touch and transform your manufacturing process today.

Contract Manufacturing

Let us look after some or all of your manufacturing process

We develop and manage your manufacturing process, with our integrated networks of qualified and reputable factories providing quality engineering services to deliver both components and full product assemblies.

Talk to us about:

- Casting, machined components and tooling

- Manual or CNC cutting

- Pressed and formed parts

- Heavy and light fabrication

- Prototyping and modelling CAD services

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.

ENQUIRE NOW

Contact Form

SIGN UP TO OUR NEWSLETTER

Newsletter Form

CONTRACT MANUFACTURING

STRATEGIC SOURCING

Helping manufacturers compete globally through Strategic Sourcing.

We make global sourcing it as easy buying from a local supplier.

Strategic sourcing means that we cover the contract manufacturing, the logistics and you pay in your currency.

We provide confidence and trust in the products we supply because we expect our suppliers to be knowledgeable about their industry and the products they manufacture. We require a high level of communication and integrity from each factory to enable us to better serve our customers.

Quite simply; quality product, on time, at the right price consistently.