WALLGUARD

Breaking boundaries, not walls. Modern thinking, communication, and

professionalism drive quick market readiness of innovative WallGuard

product.

Kapiti Colour is a painting services company which has been operating for 7 years and caters to a wide range of clients including retirement villages like Rymans and Sommerset. Georgia Baird, the owner, and her husband Tommy lead a small team that assists them in delivering premium painting services. With firsthand experience in retirement village environments, they recognised the need for a solution to address consistent damages to walls caused by hospital equipment.

Georgia’s background in design and her husband’s expertise came together to identify a pressing problem: minimising everyday damage caused by hospital beds banging into walls. Seeking a solution, they envisioned WallGuard, a rubber based buffer that would act as a protective layer between wheels and bed heads. With its non-porous and easy-to-clean features, WallGuard aimed to significantly reduce the cost and inconvenience associated with frequent wall repairs.

Kapiti Colour approached Linkeight, seeking assistance in manufacturing the optimal product. Georgia first noticed Linkeight’s presence in the Kapiti area via a sign written car and rubbed shoulders with Director Jeremy at business events, from there she explored their website and after an initial friendly chat, she realised that Linkeight could be the perfect partner for the WallGuard project.

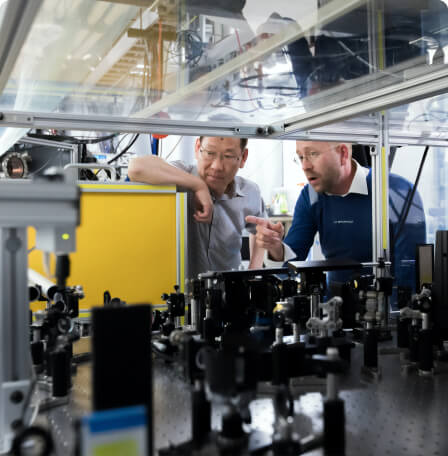

Jeremy’s expertise and prior knowledge of rubbers and manufacturing processes were instrumental in bringing the project to life. Linkeight were able to quickly provide valuable insights and ideas, bridging the gap between design and overseas manufacturing. They facilitated the prototyping and pricing process, ensuring efficient communication and a quick turnaround through to production. Linkeight managed the entire manufacturing process with their trusted Chinese factory partners and also covered the logistics and shipping, ultimately delivering the product right to Kapiti Colour’s door.

The collaboration between Kapiti Colour and Linkeight was seamless, thanks to upfront communication and reassurance from Jeremy. The entire process, from idea inception to product delivery, took approximately 6 months, showcasing the efficiency and professionalism of Linkeight in the contract manufacturing space.

Georgia particularly appreciated Jeremy’s straightforward communication style, his ability to ask the right questions, and the ease of decision-making that resulted from their interactions.

“I feel that Linkeight distinguishes themselves from other contract manufacturing companies through their modern thinking, communication, and approachability. Jeremy’s relaxed personal demeanour creates an environment where clients feel comfortable and supported. The efficient and professional nature of their operations adds to the overall positive experience of working with Linkeight”

“Arrange a phone call or meeting with Jeremy, as his expertise and attitude inspire reassurance. Linkeight thrives on challenges and problem solving, making them an ideal partner. Their dedication, communication skills, and professional expertise make them a valuable asset to any project”

Contract Manufacturing

Let us look after some or all of your manufacturing process

We develop and manage your manufacturing process, with our integrated networks of qualified and reputable factories providing quality engineering services to deliver both components and full product assemblies.

Talk to us about:

- Casting, machined components and tooling

- Manual or CNC cutting

- Pressed and formed parts

- Heavy and light fabrication

- Prototyping and modelling CAD services

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.