TORUS PET

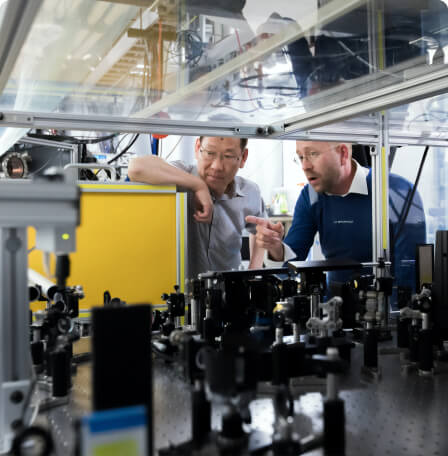

Refreshing approach to business opens up opportunities for efficiency.

Nathan Lawrence, Owner and Director of Torus Pet, has spent the past two years working closely with Linkeight during an intense rebuild process for the company.

Prior to that, Linkeight CEO Jeremy supported the previous owners of the business for over seven years in various capacities. Nathan is happy to acknowledge that Jeremy’s input throughout the last 24 months has been incredibly supportive and helpful for the company as they strive to drive efficiencies and improvements.

Torus Pet design and market a range of pet products worldwide which support pet hydration. Over the past two years their focus was to look at alternative models for their manufacturing process as well as the sourcing of packaging stock.

Linkeight were referred by an engineer in Porirua. It’s been a challenging and fun journey for both companies since they first started working together, Nathan adds

“Jeremy is very genuine and that counts for a lot. He’s an engineer and so he understood and had knowledge in the space we operate in from a technical perspective. His commercial acumen, connections and network in China gave me reassurance of a safety net for any decision we made regarding manufacturing. His engineering background provided an extra layer of certainty because he knew what we needed at that level too.”

It's all about trust.

For Nathan, that knowledge and experience counts for a lot, but it goes deeper than that. It’s about trust.

Like many New Zealand businesses, Nathan admits his knowledge of operations in China is limited. “Linguistically and culturally, there are many divides, but Jeremy’s professionalism and responsiveness mean those divides unite what we do rather than the opposite.”

Taking the leap of faith to move any part of a business offshore requires planning, knowledge and transparency, Nathan took his time to make sure it was the right decision for Torus Pet. He was reassured by Linkeight’s detailed briefs, regular communication, pricing transparency and their responsiveness. In short, “We were never left hanging.”

“I trust Jeremy and that’s the reason we continue to work together. He looks after our assets with such a high degree of integrity and sensitivity regarding our IP and this speaks volumes about him, the person he is and the way he does business. He is really invested in us and in the relationship.” – Nathan Lawrence, Owner and Director of Torus Pet

They've never looked back.

Nathan says of Linkeight “I’d recommend them in a heartbeat. If you are looking for alternative sourcing options or want to re-think an element of your production give these guys a call. We haven’t looked back since that first referral.”

For more information on Torus Pet visit: www.toruspetglobal.com

Contract Manufacturing

Let us look after some or all of your manufacturing process

We develop and manage your manufacturing process, with our integrated networks of qualified and reputable factories providing quality engineering services to deliver both components and full product assemblies.

Talk to us about:

- Casting, machined components and tooling

- Manual or CNC cutting

- Pressed and formed parts

- Heavy and light fabrication

- Prototyping and modelling CAD services

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.