FROSTBOSS

How one NZ manufacturer found clarity and confidence in China with Linkeight

When Mike Sutherland boarded a plane to China earlier this year, he wasn’t chasing cheap labour or quick wins — he was looking for certainty.

FrostBoss NZ – a global leader in frost protection fans to help protect high-value crops from damaging frost events – Mike knew that scaling the manufacturing operations offshore could unlock real growth. But he also knew the risks. Would the quality meet their standards? Could a supplier deliver consistently at scale? Was it worth the leap?

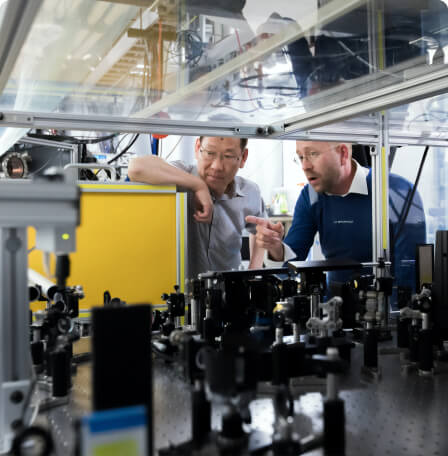

The scale and professionalism of Chinese manufacturing facilities often surprises New Zealand business operators.

Discussing production requirements with a key supply partner.

That’s where Linkeight came in

The New Zealand-based outsourcing specialists don’t just connect businesses with offshore manufacturers, they walk alongside them, providing structured, expert-led factory tours designed to remove the guesswork.

For Mike, the opportunity to travel with Linkeight and visit potential manufacturing partners on the ground offered something no spreadsheet or supplier pitch could: confidence.

““Before the trip, we had questions around quality, capacity, and whether the manufacturer could truly meet our standards long-term.” he says. “Seeing the operation firsthand gave us full confidence in moving ahead.””

The tour wasn’t a sightseeing mission — it was a focused, strategic experience. Over several days, Mike toured factories, reviewed samples, met key suppliers face-to-face, and got a real feel for their capabilities. Just as importantly, he had the support of Linkeight’s experienced team to interpret, advise, and ask the right questions.

“I didn’t feel like a tourist — I felt like a business owner making well-informed decisions with the right people beside me”

And those decisions had an immediate impact. With greater certainty around lead times, cost structures, and production capabilities; FrostBoss was able to make clear, confident moves — setting the business up to deliver more consistently for customers back home.

“We now have more visibility around our production roadmap. That kind of insight is incredibly powerful when you’re trying to grow.” Mike says.

Linkeight’s curated tours are designed specifically for New Zealand businesses like Mike’s — companies that need more than a manufacturer. They need a partner they can trust. For FrostBoss, the experience has not only decreased risk in their supply chain — it has opened up new possibilities for scale, efficiency, and long-term resilience.

Looking back, Mike is clear on what made the difference.

“If you’re serious about outsourcing, you have to go. Don’t make decisions from behind a desk — get over there and see it for yourself.”

One of the benefits of travelling to China with Linkeight is being able to discuss detailed production requirements in person

For more information on FrostBoss please visit: www.frostboss.com

Industrial Product Sourcing

Off-the-shelf product solutions at the most profitable level.

Industrial Product Sourcing with Linkeight provides you a business and support system that manages the risk of dealing with global manufacturers. It is a method that focuses on sourcing quality products, and delivering them on time, at the right price, consistently.

Talk to us about:

- Factory fit

- Sampling

- Quality assurance

- Shipping and logistics

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.