Imagination Gin

Navigating Growth: Imagination Gin and Linkeight’s

strategic partnership

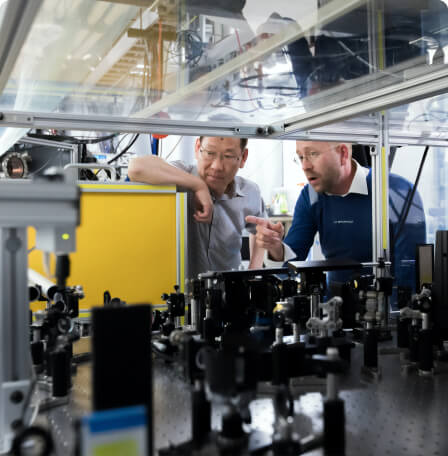

Imagination Gin operates as a manufacturing business, handling all production internally through a full end-to-end process. Primarily functioning as a wholesaler, they also generate substantial revenue through retail channels, including online stores and duty-free outlets. Jeremy and the Linkeight team collaborate closely with Imagination Gin on their manufacturing operations, focusing on improving efficiencies, optimising processes, and sourcing equipment from suppliers in China. Chris highlights the pivotal role of the Linkeight partnership, detailing how it has played a crucial role in supporting their growth strategy by providing cost effective solutions that enable the business to achieve necessary efficiencies and sustain its expansion.

According to Chris, “Jeremy feels more like a partner than just a supplier to us. His local presence and hands-on approach have been instrumental in driving innovation and efficiency improvements.”

Chris further explained that Jeremy often suggests solutions that extend beyond process improvements, including strategies to optimise cost structures – a critical focus during economic challenges.

Chris praises Jeremy’s pivotal role in assisting the team during challenging situations. When Imagination Gin integrated their label machine, they faced initial operational challenges.

Chris expressed, “Jeremy was up there for hours on end helping us get through those teething issues with the machine and making it work for our production process - it’s that ongoing partnership that goes past the first sale.”

Currently, Imagination Gin and Linkeight are collaborating on custom-made bottles and stoppers aimed at reducing production costs and increasing profit margins in a competitive market. This initiative reflects their proactive approach to navigating economic uncertainties.

Chris emphasises Linkeight’s unique value proposition as a New Zealand-based supplier in a predominantly Chinese manufacturing landscape. He highlights the added value of local accessibility, clear communication, reliable guarantees, and competitive pricing comparable to Chinese suppliers, while maintaining high product quality standards.

Chris explains that “in our industry there is a lot of equipment that comes out of both China and Europe. I’ve heard of nightmare stories of equipment coming out of Europe through a New Zealand distributor and there’s no ongoing support afterwards and they’re also three to five times more expensive than what we pay out of China.”

“I would 100% recommend Linkeight. I think as far as suppliers go and building that supplier relationship, they’re one of the top suppliers I have, the communication is there, the quality is there and the problem solving is also there.”

The successful partnership between Linkeight and Imagination Gin exemplifies how strategic collaboration can drive innovation and efficiency in the manufacturing sector. By leveraging Linkeights local presence and expertise, Imagination Gin has navigated its rapid growth and operational challenges with success.

Contract Manufacturing

Let us look after some or all of your manufacturing process

We develop and manage your manufacturing process, with our integrated networks of qualified and reputable factories providing quality engineering services to deliver both components and full product assemblies.

Talk to us about:

- Casting, machined components and tooling

- Manual or CNC cutting

- Pressed and formed parts

- Heavy and light fabrication

- Prototyping and modelling CAD services

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.