PACIFIC ENERGY SOLUTIONS

Offshore manufacturing concerns eliminated through Linkeight factory assessment and consultancy.

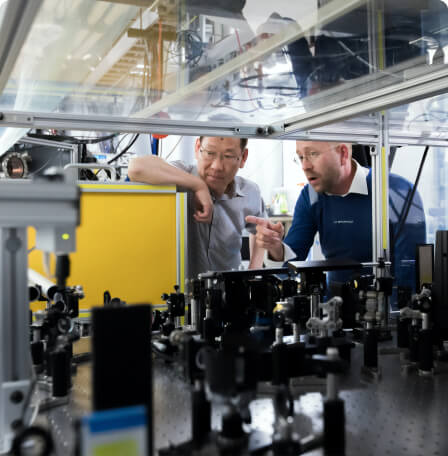

Pacific Energy Solutions Director, Perry Hutchinson has been working on an innovative new development for around 18 months involving specialist machinery.

During the initial development stages Perry looked at having his machinery manufactured in New Zealand but soon realised that the cost involved would be prohibitive in bringing the product to market at a sustainable price point.

Perry began to investigate manufacturing the machinery in China and found a factory there himself that indicated they could produce it. With little experience in dealing with Chinese manufacturers, the international logistics landscape and cultural differences, Perry became nervous and decided he needed expert advice.

Perry had an existing relationship with Jeremy from Linkeight who he’d known for about four years, he reached out to Jeremy and provided a brief of the project. Jeremy recommended a factory audit and assessment be conducted by Linkeight staff on the ground in China.

Linkeight carried out due diligence on the factory and its operations – liaising directly with the factory to establish its manufacturing quality, machinery, technology and provided an on-site audit which included a full report containing imagery and video.

The Linkeight team also reviewed the sample machinery that the factory had produced to inspect the quality and iron out any small issues that arose due to language/communication differences. The outcomes of the factory audit and assessment by Linkeight gave Perry confidence in the selection of factory.

International logistics made easy.

Perry was happy with the quality of the manufactured machinery and decided to go ahead and place a first unit prototype order. At this stage however Perry faced a conundrum around the logistics of shipping to New Zealand.

“I realised that I had little idea of how we were actually going to ship the machinery to New Zealand. I knew there were elements with international freight such as insurances and shipping schedules and preferred that someone else take care of that for me as it’s not my forte.”

Perry engaged Linkeight to book and manage the delivery of the machinery to New Zealand, they were happy to oblige.

“Jeremy and the Linkeight team took care of everything from the machinery leaving the factory in China right through to delivery to our door. They arrived on time and they are a very well made product, the quality really stood up.”

Perry is now looking at importing the machinery in bulk moving forward and admits it would have been difficult to get to that point without the assistance of Linkeight.

“We took a big risk in manufacturing the machinery over in China and placed a great deal of trust in Linkeight, the risk has paid off. Jeremy is honourable, trustworthy and has a vast knowledge of manufacturing and supply chains in China which was crucial to the successful outcome of the unit production and shipping.”

Professional and easy to deal with.

For others looking to engage Linkeight’s services for sourcing or manufacturing in China, Perry’s advice is simple.

“I would highly recommend Linkeight to anyone who is nervous or overwhelmed by the prospect of manufacturing offshore, they took the stress out of the process and covered all the details. They are professional and extremely easy to deal with, their communication is on point at every stage of the process and you’re always kept in the loop.”

“Linkeight provided us with invaluable advice and support in sourcing specialised machinery from China. This was the first time we had sourced anything from China and naturally had a number of concerns due to our inexperience.”

For more information on Pacific Energy Solutions visit: www.pacificenergy.co.nz

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Factory Consultancy & Assessment

Are you looking to manufacture a product offshore?

Linkeight can take the stress out of dealing with China by qualifying a factory for the production of your product. We provide reports of our findings, including relevant photographs, videos, copies of relevant documentation and any other requested materials.

Talk to us about:

- Factory capability assessment

- Factory qualification assessment

- Production monitoring

- Company information and legal status reports

FREQUENTLY ASKED QUESTIONS

Physical factory visits, photo and or video reviews, discipline alignment, process review.

Clients provide Linkeight a brief including the product that they’re looking to manufacture, and the details of the chosen factory they would like to use. Linkeight then review the factory based on the agreed key production requirements and provides feedback to the client.

Contract manufacturing facilities, factories which will provide parts for multiple customers.

A pdf document outlining finding and recommendations will be supplied including photographs and or videos to accompany.

We have experts on the ground in China who can physically visit the factories. With more than 15 years experience dealing with Chinese manufacturers we can mitigate the risks of manufacturing offshore.

The cost of a standard report is $500 USD + travel charges to the factory location.

Dependent on factory availability you could expect a report within 1 week of the factory visit.